Product Design | Waterfalls

As the Senior Design Engineer at Harmonic Environments, I specialized in the design and engineering of custom stainless-steel waterfalls and wine coolers. For over 9 years, I provided a mixture of initial concept sketches, site visits, shop drawings, parametric 3D modeling, prototyping, project management, and installation consultation to bring architectural products to life.

Due to the challenging nature of custom manufacturing, I followed each product from initial design phase, through the manufacturing plant, to final installation while resolving unforeseen issues along the way.

In short, my role was to develop each project from concept to completion. This led me to continually examine my work to refine the design details, identify alternate processes, and plan for future obstacles.

Working as the Senior Design Engineer allowed me to use the critical thinking, problem solving, technical and spatial skills that I’ve attained through my architectural training, while also continuing to make an impact on the spaces we live, work, and play.

Harmonic Environments is a division of EMJAC Industries, a family owned and operated stainless-steel fabricator.

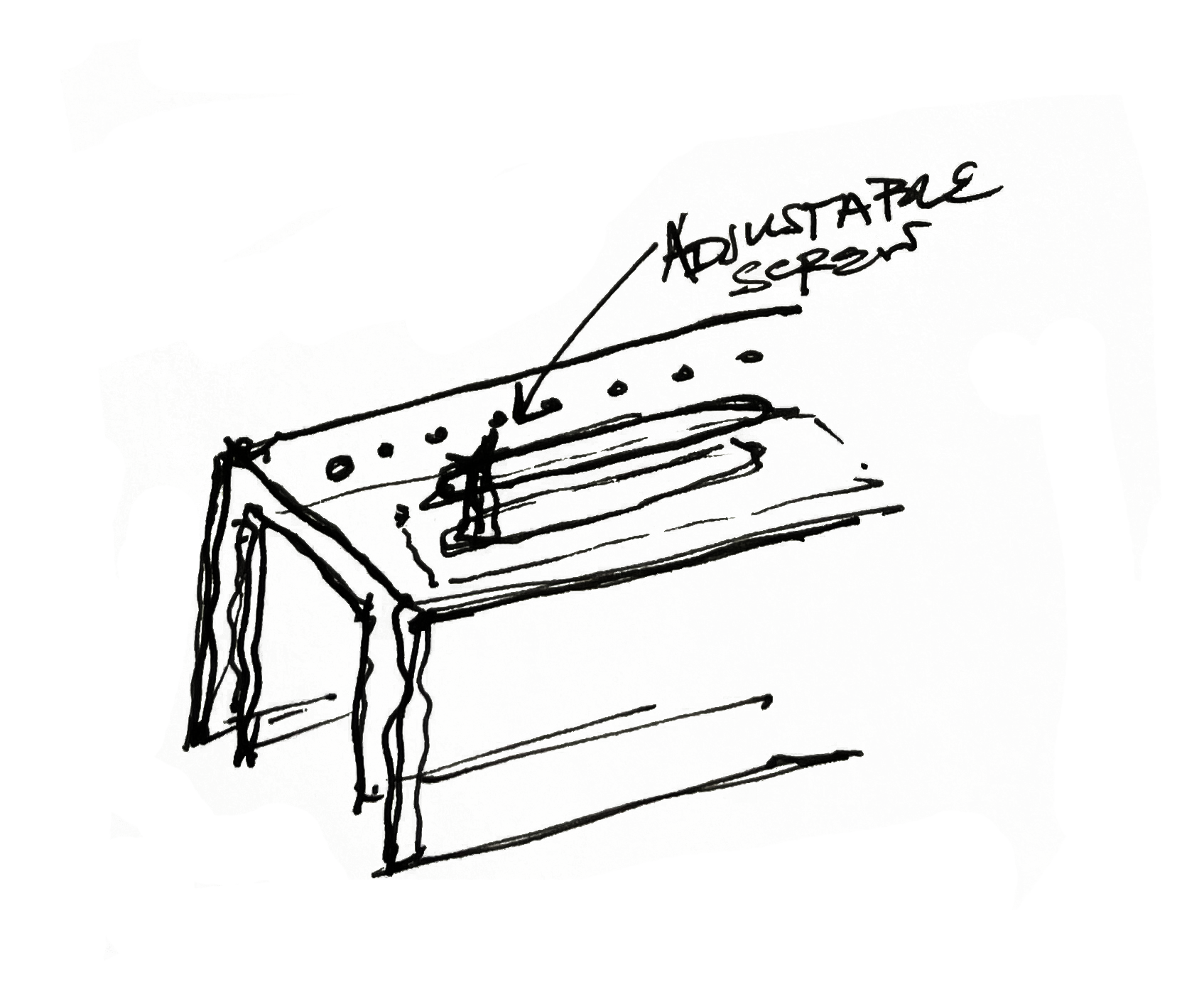

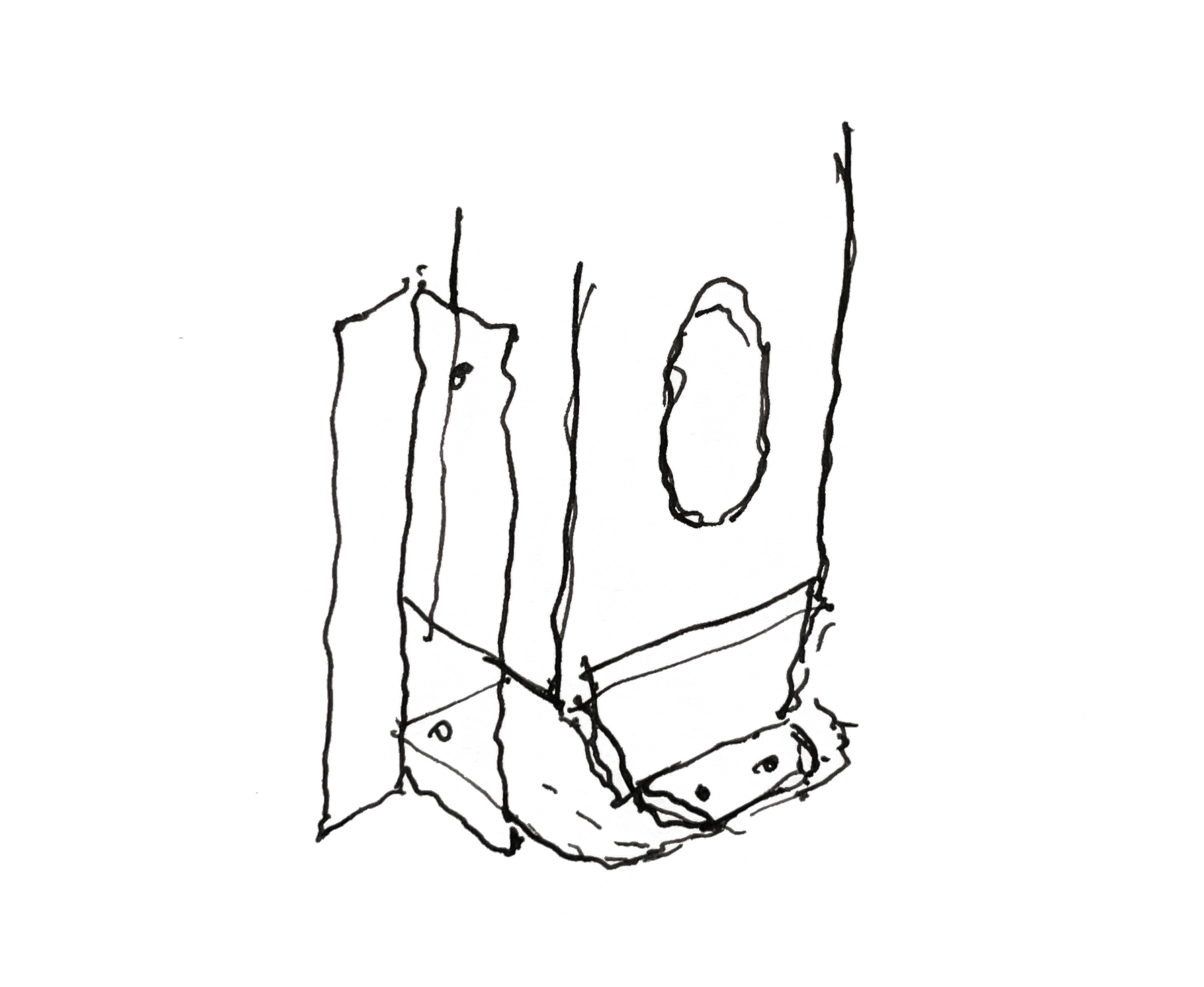

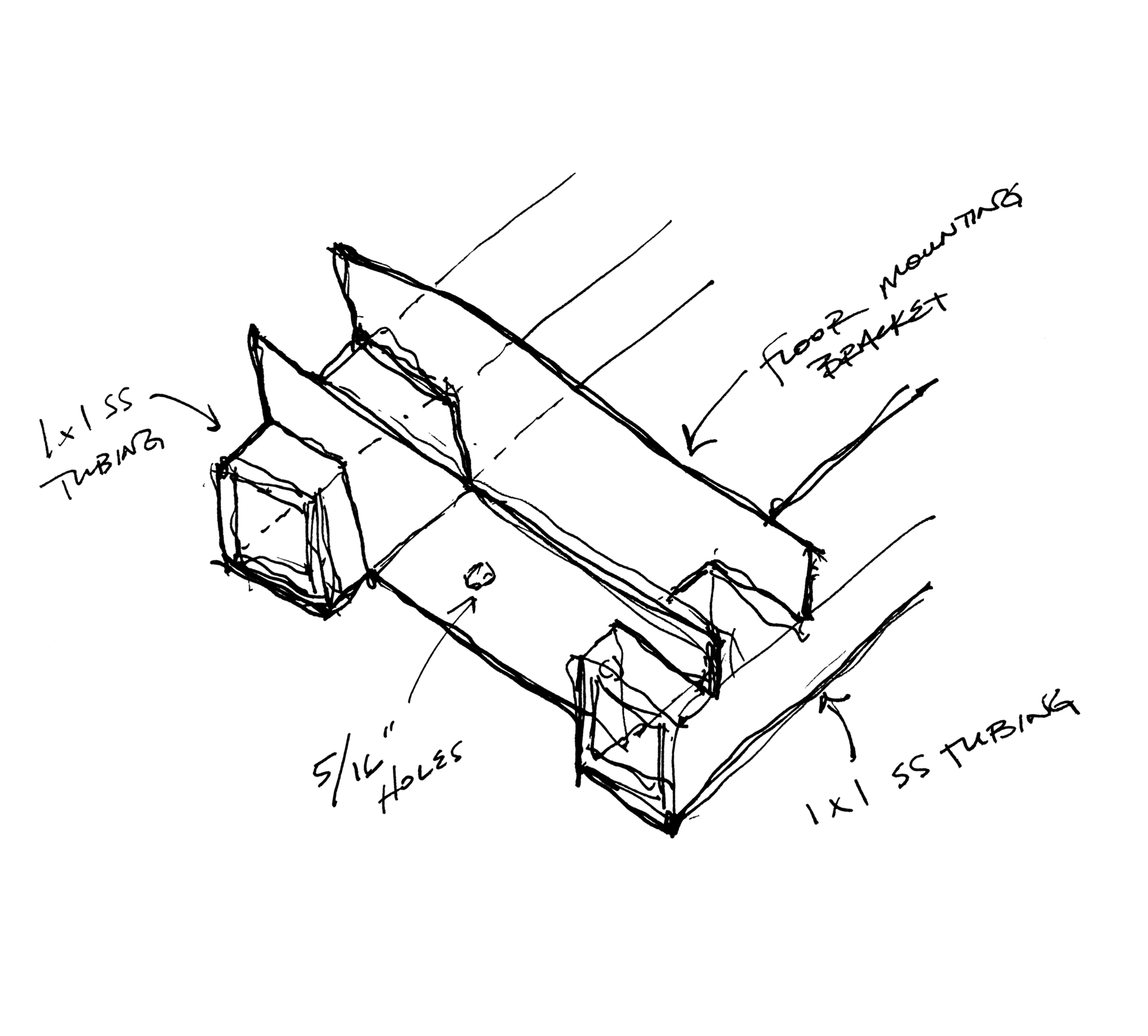

Below are a selection of process images illustrating the phases of design and engineering to arrive to the finished waterfall.

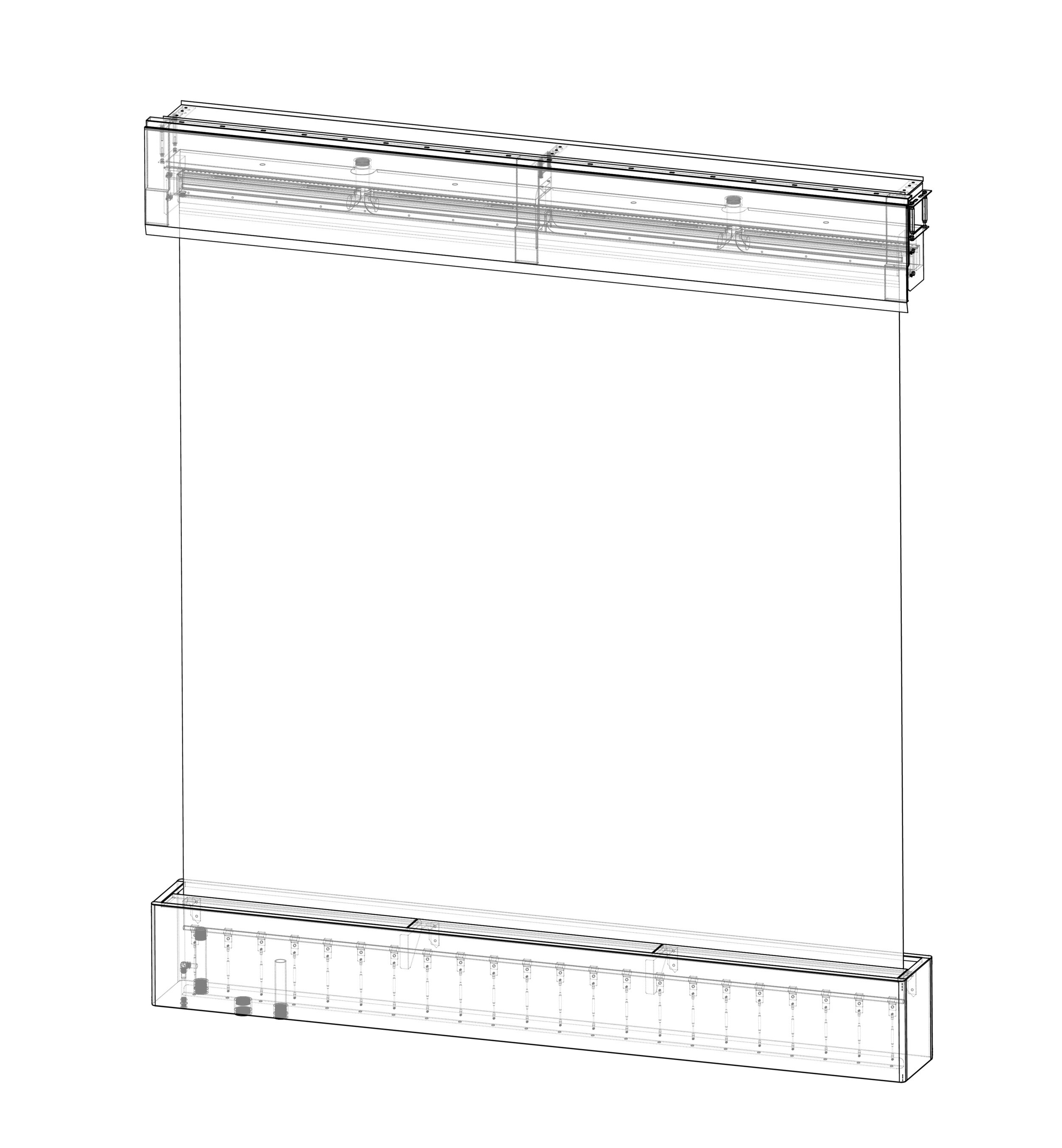

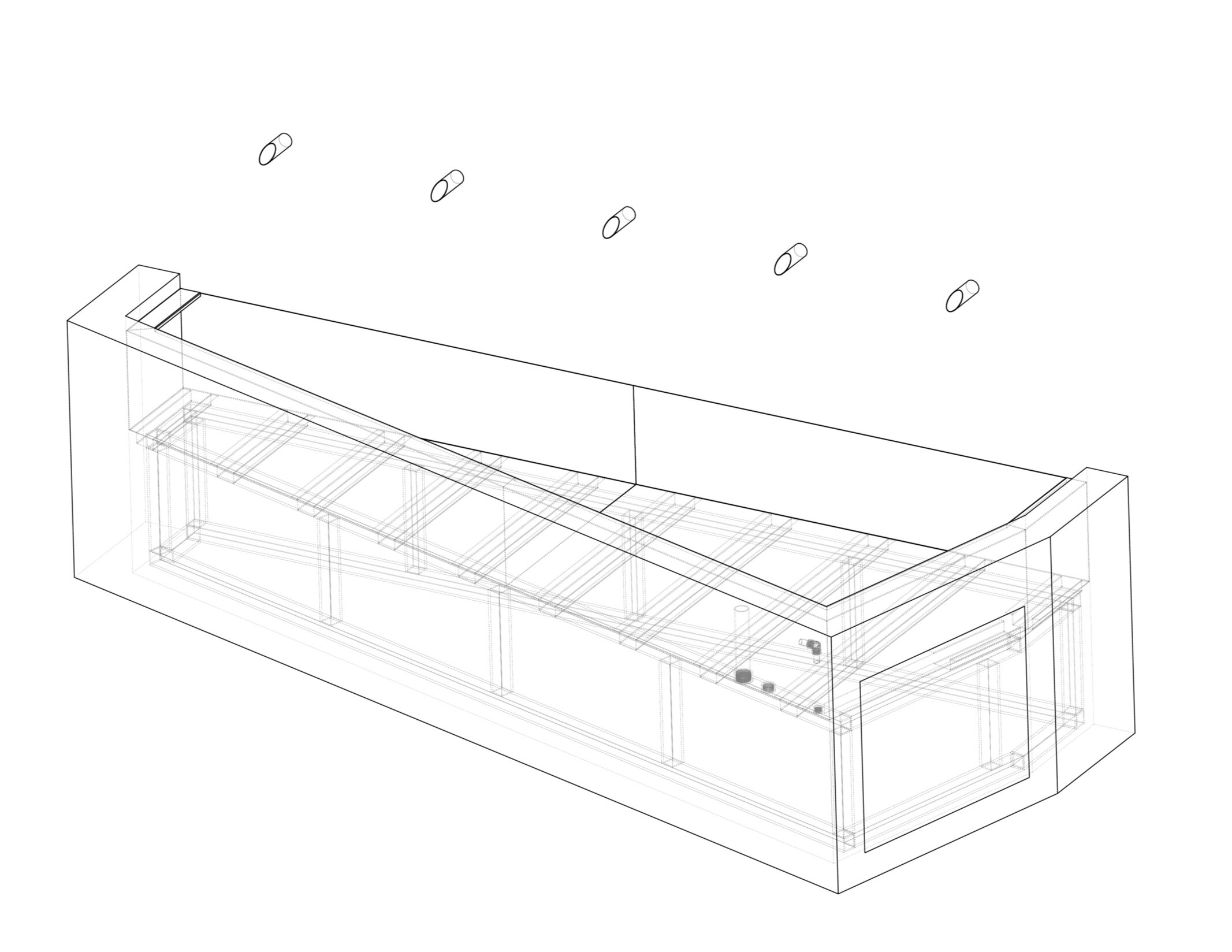

The first set of images below are select sketches of concept ideas and design details. The second set are examples - pulled from shop drawings - illustrating elevations, sections, and electrical diagrams using AutoCAD. The third set are examples of CREO

parametric 3D models. The CREO models are utilized to engineer each waterfall for final breakdown before releasing to the plant for fabrication. The last set of images are example jobs during or after final installation.